FLAME RETARDANT PLASTICS

FLAME RETARDANT PLASTICS

Our technical team has created a range of ABS and PC materials that meet the UL94 vertical burn standards. These materials are excellent choices for electronics, building materials and other products where safety is a concern.

Our technical team has created a range of ABS and PC materials that meet the UL94 vertical burn standards. These materials are excellent choices for electronics, building materials and other products where safety is a concern.

Innomerix uses the UL94 vertical burn method to determine the flame retardance of our compounds. This test involves exposing a test piece to a flame for 10 seconds and measuring the time taken for the flame to extinguish. The flame is the applied a second time and the self-extinguish time is taken a second time. The material is then rated based on the burning behaviour. Materials are rated based on the criteria laid out in the table below.

Innomerix uses the UL94 vertical burn method to determine the flame retardance of our compounds. This test involves exposing a test piece to a flame for 10 seconds and measuring the time taken for the flame to extinguish. The flame is the applied a second time and the self-extinguish time is taken a second time. The material is then rated based on the burning behaviour. Materials are rated based on the criteria laid out in the table below.

| Test Criteria |

V-0 |

V-1 |

V-2 |

| Burning time of each individual test specimen (s) (after first and second flame applications) |

≤ 10 |

≤ 30 |

≤ 30 |

| Total burning time across 5 samples (s) (10 flame applications total) |

≤ 50 |

≤ 250 |

≤ 250 |

Burning and afterglow times after second flame application (s) | ≤ 30 | ≤ 60 | ≤ 60 |

Dripping of burning specimens | no | no | yes |

Combustion up to holding clamp (specimens completely burned) | no | no | no |

Test Criteria |

V-0 |

V-1 |

V-2 |

Burning time of each individual test specimen (s) |

≤ 10 |

≤ 30 |

≤ 30 |

Total burning time across 5 samples (s) |

≤ 50 |

≤ 250 |

≤ 250 |

Burning and afterglow times after second flame application (s) | ≤ 30 | ≤ 60 | ≤ 60 |

Dripping of burning specimens | no | no | yes |

Combustion up to holding clamp (specimens completely burned) | no | no | no |

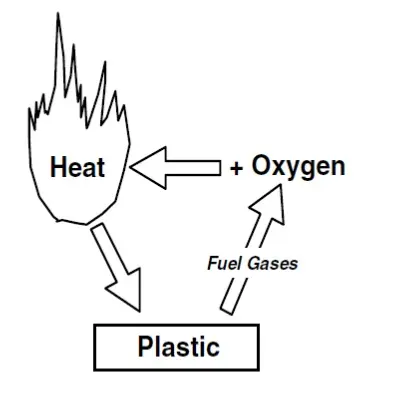

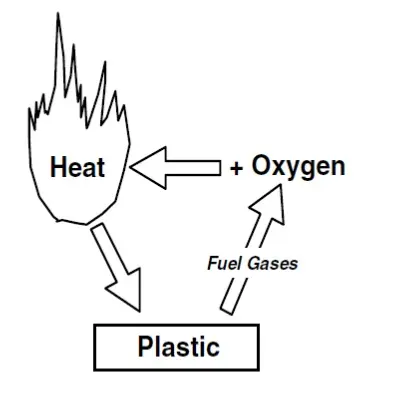

Plastics are commonly used in building materials, electronic housing, and mining equipment. All these applications expose the plastic to sources of ignition which have the potential to ignite the material. When plastics are subjected to heat, they produce volatile gasses that are easily ignited. As these gasses ignite, more heat is produced creating a feedback loop, causing the plastic to burn rapidly.

Plastics are commonly used in building materials, electronic housing, and mining equipment. All these applications expose the plastic to sources of ignition which have the potential to ignite the material. When plastics are subjected to heat, they produce volatile gasses that are easily ignited. As these gasses ignite, more heat is produced creating a feedback loop, causing the plastic to burn rapidly.

Plastics Combustion Mechanism

Feedback cycle showing the combustion mechanism of plastics. Heat causes the plastics to release flammable gasses, that readily ignite. This produces more heat and causes the cycle to continue.

Ref: Handbook of Building Materials for Fire Protection, Charles A Harper,2004.

Plastics Combustion Mechanism

Feedback cycle showing the combustion mechanism of plastics. Heat causes the plastics to release flammable gasses, that readily ignite. This produces more heat and causes the cycle to continue.

Ref: Handbook of Building Materials for Fire Protection, Charles A Harper,2004.

Through the additional of functional additives, this reaction can be controlled or even quenched. Free radical scavengers can suppress the reaction in the gas phase by quickly reacting with the fuel gasses produced during the thermal decomposition. Other additives can absorb heat and produce water to reduce the heat, or produce inert char layers on heating, preventing the formation of the fuel gasses required to ignite. The type of flame-retardant system used depends on the requirements of the end-product.

There are a range of flame-retardant standards used in Australia, covering a variety of uses. Our technical team is dedicated to developing material suitable for your needs.