IMPACT MODIFIED ACRYLONITRILE

BUTADIENE STYRENE (MABS)

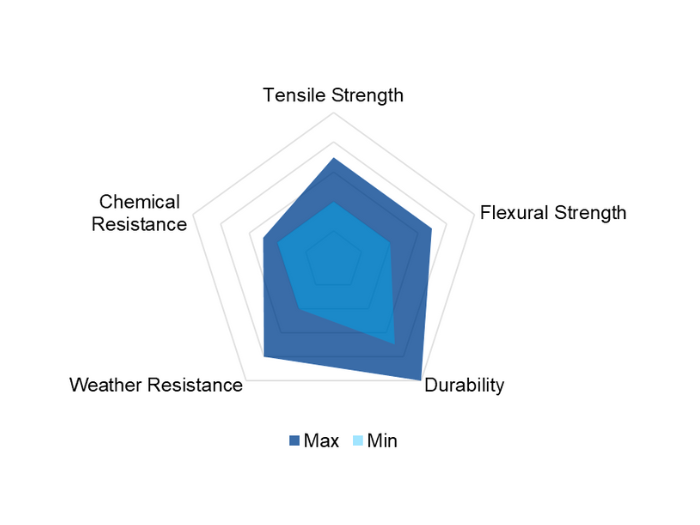

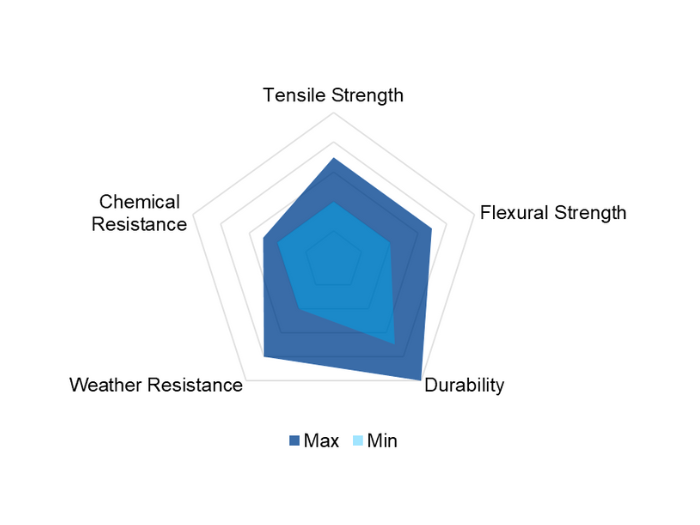

Impact Modified Acrylonitrile Butadiene Styrene (MABS) compounds integrate ABS with impact modifiers to enhance toughness and resilience. This modification results in a material that maintains the inherent strength of ABS while exhibiting improved resistance to impact and shock. MABS compounds are particularly well-suited for applications where durability and resistance to mechanical stress are essential, making them a valuable choice in 3D printing.

Impact Modified Acrylonitrile Butadiene Styrene (MABS) compounds integrate ABS with impact modifiers to enhance toughness and resilience. This modification results in a material that maintains the inherent strength of ABS while exhibiting improved resistance to impact and shock. MABS compounds are particularly well-suited for applications where durability and resistance to mechanical stress are essential, making them a valuable choice in 3D printing.

IMPACT MODIFIED ACRYLONITRILE BUTADIENE STYRENE

PRODUCTS

IMPACT MODIFIED ACRYLONITRILE BUTADIENE STYRENE PRODUCTS

Improved impact strength

Excellent durability

Low cost

Suitable for injection moulding, extrusion, and additive manufacturing

Improved impact strength

Excellent durability

Low cost

Suitable for injection moulding, extrusion, and additive manufacturing

MABS compounds are used in the production of protective gear and equipment, where resistance to impact is crucial. In the automotive sector, MABS is employed for manufacturing impact-resistant components, such as bumpers and interior parts. The consumer goods industry utilizes MABS for creating durable and tough prototypes and end-use products.

Innomerix’s modification of ABS enhances the material's toughness, gives a lower weld temperature and superior dimensional stability. This makes MABS compounds an excellent choice for large scale 3D printing, allowing for large, durable parts to be printed with ease.