GLASS REINFORCED POLYCARBONATE

(PC-GF)

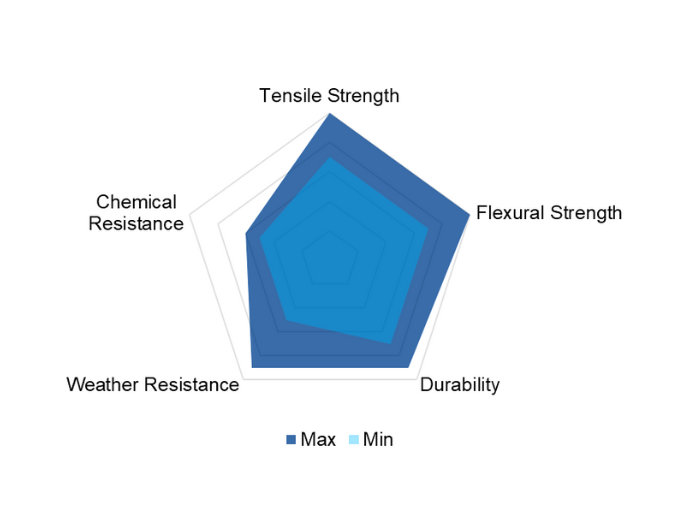

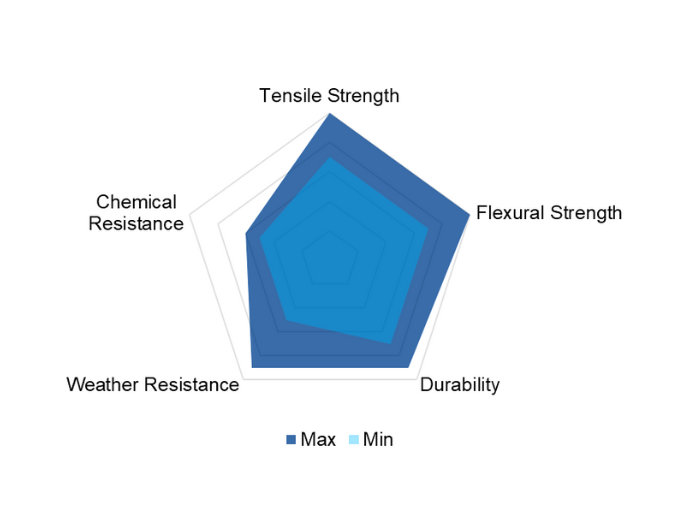

Glass Reinforced Polycarbonate (PC-GF) compounds blend the inherent strengths of polycarbonate with the added reinforcement of glass fibres, resulting in a composite material with greatly improved mechanical properties. This combination enhances the material's tensile strength, impact resistance, and dimensional stability, making it well-suited for demanding applications.

Glass Reinforced Polycarbonate (PC-GF) compounds blend the inherent strengths of polycarbonate with the added reinforcement of glass fibres, resulting in a composite material with greatly improved mechanical properties. This combination enhances the material's tensile strength, impact resistance, and dimensional stability, making it well-suited for demanding applications.

GLASS REINFORCED POLYCARBONATE PRODUCTS

GLASS REINFORCED POLYCARBONATE PRODUCTS

Very high mechanical strength

Excellent dimensional stability

Very high heat deflection temperature

Suitable for injection moulding, extrusion, and additive manufacturing

Very high mechanical strength

Excellent dimensional stability

Very high heat deflection temperature

Suitable for injection moulding, extrusion, and additive manufacturing

PC-GF can be used to downsize existing plastic parts while retaining strength and has also been used as substitution for aluminum and other metals. In the automotive sector, it is utilized for producing robust and impact-resistant component. The aerospace industry benefits from the material's lightweight properties coupled with enhanced strength for applications where a high strength-to-weight ratio is essential. The electrical and electronics industry leverages PC-GF for manufacturing parts that demand both mechanical strength and electrical insulation.

The incorporation of glass fibres into polycarbonate broadens its potential applications in 3D printing, offering a balance between strength, transparency, and versatility across different industries: