INJECTION MOULDING

INJECTION MOULDING

As pioneers in our field, we excel in the craft of crafting high-performance thermoplastic materials precisely tailored to suit your distinct demands. Be it additive manufacturing or injection molding, our state-of-the-art methodologies assure the production of exceptional goods, establishing novel standards in adaptability and lasting resilience.

As pioneers in our field, we excel in the craft of crafting high-performance thermoplastic materials precisely tailored to suit your distinct demands. Be it additive manufacturing or injection molding, our state-of-the-art methodologies assure the production of exceptional goods, establishing novel standards in adaptability and lasting resilience.

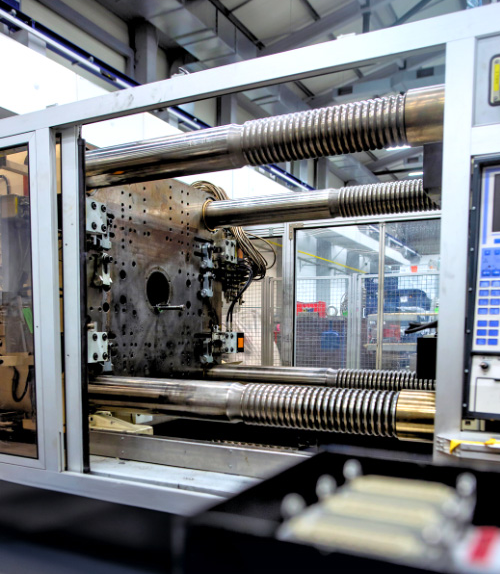

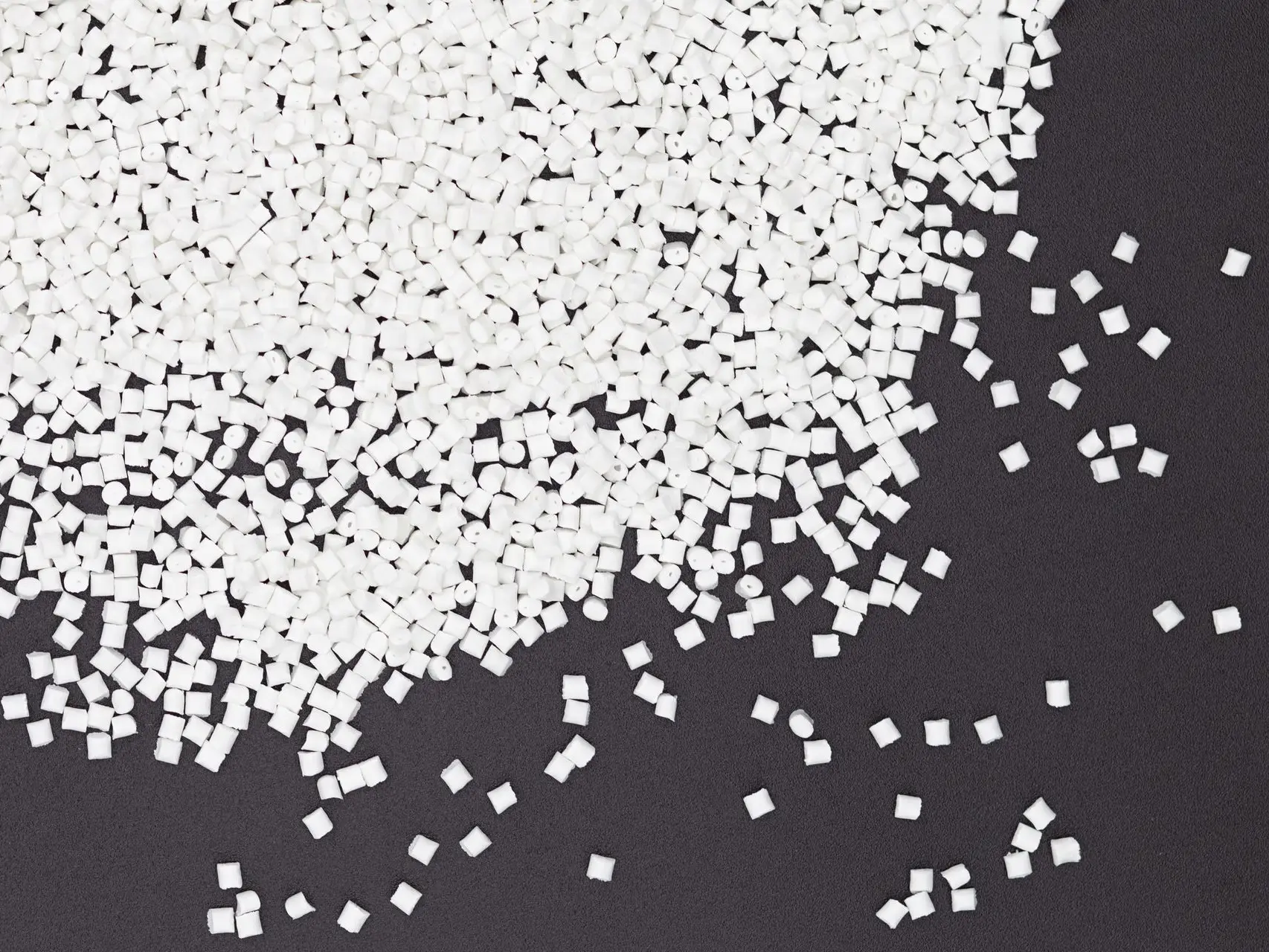

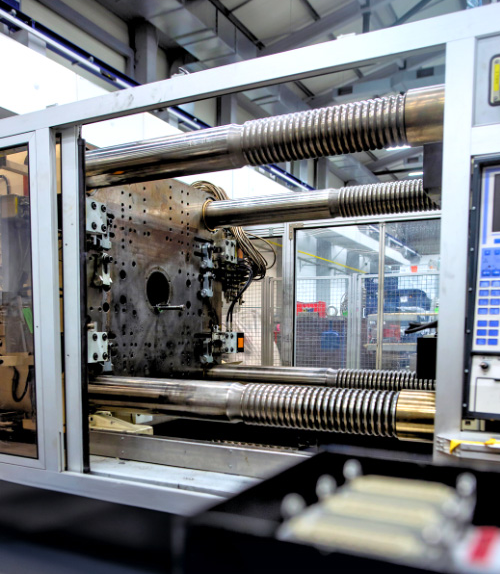

Injection moulding is a very common technique for creating thermoplastic parts. Plastic granules are fed into the barrel of the moulder. The shearing action of the screw turning generates heat in the material, causing it to melt. The melt is then injected into a metal tool and cooled to give it the desired shape.

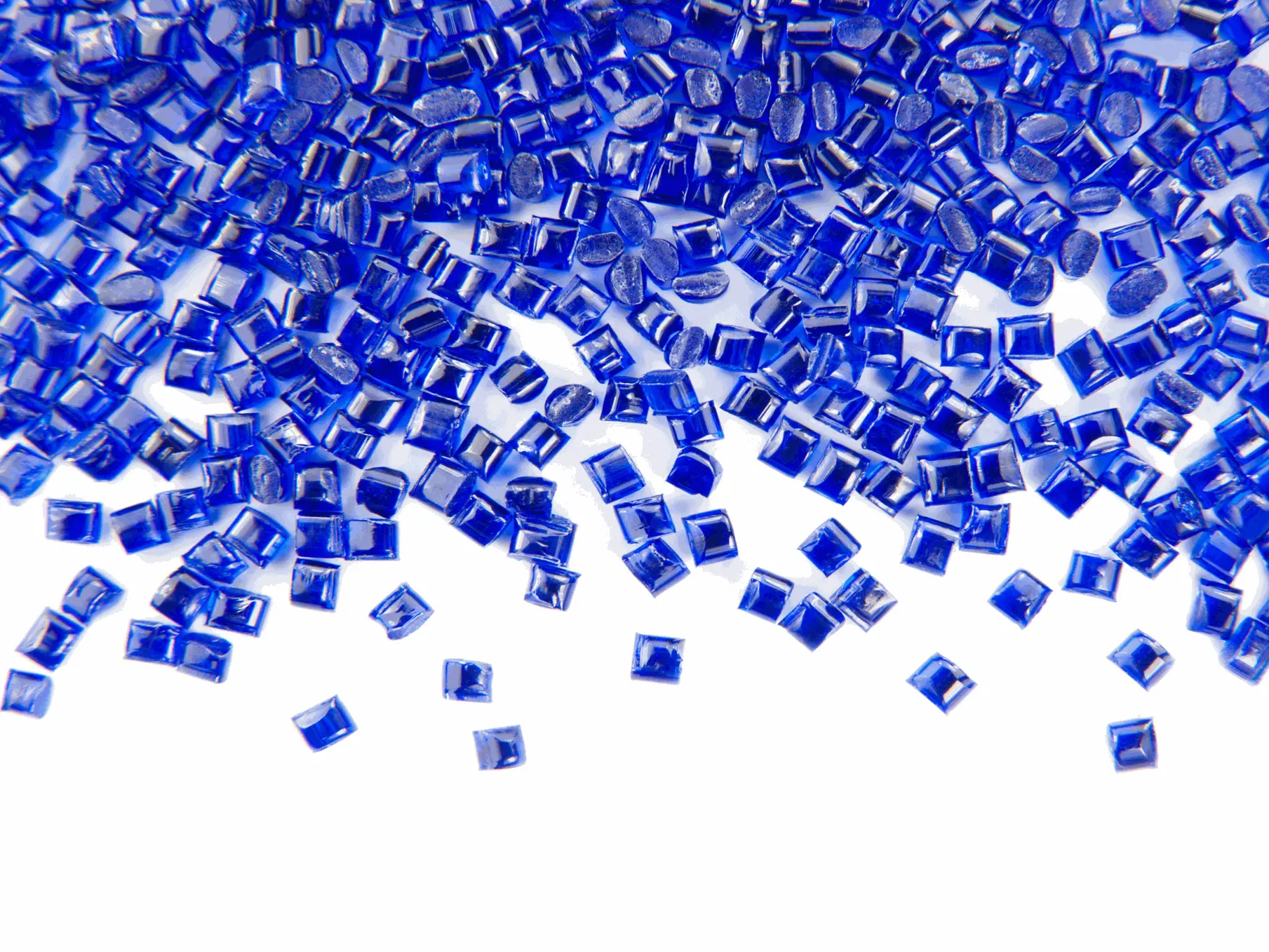

Innomerix offers a variety of material solutions for injection moulders. We work closely with colouring houses to create custom-coloured compounds. We are specialists in fibre reinforcement – creating strong lightweight thermoplastics as metal replacements or to down-weight parts.

Our process allows us to improve the outdoor life of your parts by adding UV stabilizers.

Injection moulding is a very common technique for creating thermoplastic parts. Plastic granules are fed into the barrel of the moulder. The shearing action of the screw turning generates heat in the material, causing it to melt. The melt is then injected into a metal tool and cooled to give it the desired shape.

Innomerix offers a variety of material solutions for injection moulders. We work closely with colouring houses to create custom-coloured compounds. We are specialists in fibre reinforcement – creating strong lightweight thermoplastics as metal replacements or to down-weight parts.

Our process allows us to improve the outdoor life of your parts by adding UV stabilizers.